NON HEATING TYPE IN VESSEL DRUM TYPE ORGANIC WASTE COMPOSTER

Our organic waste composter converts the biodegradable

waste or food waste into compost (fertilizer) naturally with

the help of mesophilic and thermophilic bacterias. We do not

use any external heating or other systems to create charcoal

like compost as claimed by the 24 hrs composting machines

widely spread in the market. Our food waste composter was developed after extensive research and development

carried out in the past years evolving to a better design

for a composter to ensure a natural composting process.

• “A process

in which compostable material is enclosed in a drum, silo,

bin, tunnel, reactor, or other container for the purpose of

producing compost, maintained under uniform conditions of

temperature and moisture where air-borne emissions are

controlled”

• Uses

forced aeration and/or mechanical agitation to control

conditions and promote rapid

composting

• Each

system design is different, but there are some common

elements.

Advantages

of In-Vessel Composting

• Composting

can be more closely controlled, leading to faster

decomposition and more Consistent product quality.

• Effects of

weather are diminished

• Less

manpower is required to operate the system and staff is less

exposed to composting material

• Can often

be done onsite, saving collection costs

• Less land

area is required

• Process

air and leachate can be more easily collected and treated

• Public

acceptance of facility may be better

• Can

accommodate various types and amounts of organic waste

(e.g., odorous bio solids & food)

Factors

responsible for composting

CARBON:

NITROGEN RATIO

Raw

materials blended to provide a C:N ratio of 25:1 to 30:1 are

ideal for active composting, although initial ratios of 20:1

up to 40:1 consistently give good results.

OXYGEN

Oxygen is

very important in composting because it enhances the growth

of aerobic bacteria. Aerobic bacteria are bacteria that grow

and live in the presence of oxygen and are very efficient in

breaking down waste.

TEMPERATURE

Microbial

decomposition during composting releases large amounts of

energy as heat, which raises the temperature. Composting is

most efficient when the temperature of the composting

material is between 55-60 degree Centigrade . Composting

stops if the compost becomes too cold or too hot. Hence the

temperature to be monitored.

MOISTURE

Moisture is

the lifeblood of the metabolic processes of the microbes.

Water provides the medium for chemical reactions, transport

nutrients and allows the microorganisms to move from place

to place. Efficient activity is achieved when the moisture

is maintained between 40% and 60%. More the surface area,

the faster the decomposition and the more usable compost

BIOWASTE COMPOSTER

Our organic waste or food waste composting machines uses specially designed

two way aeration system and mechanical agitation to control conditions

and promote rapid composting. Our natural organic waste

composting machine is a

combination of a device and process, targeting the quickest

transformation of biological; waste into consistent -

quality compost at the lowest possible cost and management

effort.

Salient features of

our biowaste composter compared to other systems

Disadvantages in other Machines

Advantages in

Hugros Biowaste composter

No time, microbes and

oxygen (air) provided in this system - So it is

not a composting system

We are adding microbes, providing aeration

through blowers and providing enough time for

the microbes to do their work. In our reactor we

are providing all the required biotic and

abiotic factors required for the microbes to

work.

Depends on the heating element

No heating element, The Microbes present,

themselves will produce the heat required

naturally

Just charring the waste into black

colored char by heating

Waste are not charred artificially, they are

composted

by the microbes naturally by the process of

aerobic

composting

No nutrient value in the

charred material

Very high nutrient value, with more amount of

readily

available nitrogen for plants

Power intensive, has it needs enormous

heating load

Less power intensive, as there is no heating

element

Cannot be used as a fertilizer

Can be used as High quality organic fertilizer

It’s is not a composting reactor, just

a mixer. As per the international composting

councils the temperature should be maintained

50-60 degree centigrade by removing excess heat

by circulating the air inside instead it is

fried at more than 100 degree centigrade.

We are adding microbes, providing aeration

through blowers and providing enough time for

the microbes to do their work. In our reactor we

are providing all the required biotic and

abiotic factors required for the microbes to

work (Composting).

Needs larger area for curing

No large area needed, only limited space needed

for storage bins

No provision provided to control odour

and obnoxious gases produced during composting

or mixing process

Our reactor has an inbuilt Biofilter, which

removes all

the odour and scrubs the obnoxious gases

produced

during composting or mixing process. Our

system is Odour free

Dangerous gases like SO2 are not

scrubbed, will lead to health issue

The biofilter will scrub all the obnoxious gases

like

SO2 produced during the composting process. And

releases only the odour free gases out

SPECIFICATIONS

MODEL

CAPACITY

(KG/DAY)

SPACE REQUIRED (MM)

DIMENSIONS (MM)

WEIGHT

(KG)

POWER CONSUMPTION/DAY

(Rs.)

BACTERIA CULTURE

COST/DAY (Rs.)

L

W

H

A

B

C

BC - 25A

25

2600

1800

2200

1600

800

1200

550

105

2.5

BC - 50A

50

2800

2000

2300

1800

1000

1300

650

105

5

BC – 100A

100

3250

2200

2500

2250

1200

1500

800

126

10

BC – 250A

250

4000

2500

2500

3000

1470

1750

1250

168

25

BC – 500A

500

4600

2800

3100

3600

1800

2100

1950

231

50

BC – 750A

750

5000

2900

3500

3600

2200

2600

1950

231

75

BC – 1000A

1000

5500

3000

3500

4500

2300

2600

2700

336

100

BC – 1500A

1500

5500

3000

3500

4750

2700

2600

2800

336

150

Electricity charge considered @ Rs.7/ Unit

Note:

we

suggest organic shredder to be used with machines of

100kg/day capacity or more for better composting.

Organic waste composting plant video

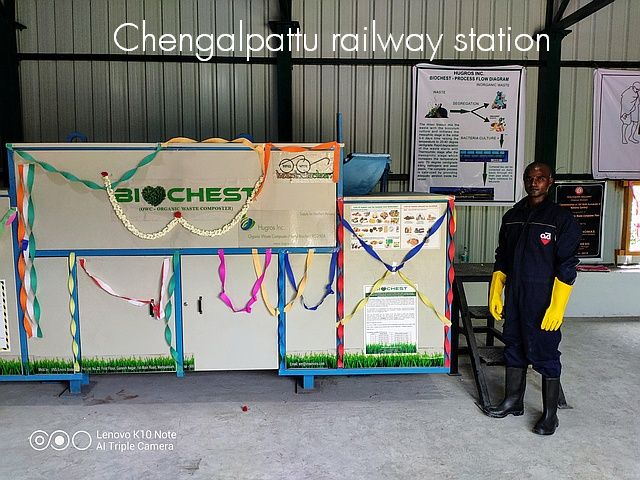

Organic waste composting machine installations at Indian railway